Donny has been busy shooting, reloading and experimenting with 6 arc and has written up a break down of his experiences with the idea of helping fellow bowlers on their quest for the 1000 yard AR15 gas gun:

For the better part of the last 6 months I have budgeted some time to see if I can improve upon factory 6ARC ammo in my 14.5 AR, and rolling my own. Some of you bowlers have followed me along this journey asking questions about my progress. I am feeling fairly comfortable with the results at this point and want to share them with you. I still have a few things to see through but I am happy with the performance out of my handloads enough to ditch shooting factory ammo for the time being. Frankly, the 108 ELDM in our experience, over the last 3 years or so we have been shooting 6ARC, has been very good ammo from a consistency perspective related to both velocity and accuracy (as of April 2025). If you don't want to take the time to reload I would say the 108s are perfectly fine. Here are some of my experiences and notes as a novice reloader.

I am using a 14.5” Noveske DDF upper with an intermediate gas system. I was given this upper and DDF barrel because it has some slight variances from a contract submission. I am very grateful to have it, currently it is my favorite semi-auto. Noveske has been at the forefront of the development of weapon systems using the 6ARC cartridge. In fact the AR Hornady has used for their reloading data was an 18” Noveske. Some military units have used them as well for whatever that's worth to you. Noveske has put a fair amount (a lot) of energy into designing a weapon that functions correctly and fixing issues as they arise.

I would say an old concern with 6ARC is the shearing of bolt lugs. At this point I have no less than 2000 rounds on this upper (probably closer to 3000) since I got it in late July and it has remained intact throughout my testing, which includes some serious increases in pressures over what is recommended out of a gas gun. More on that later. Noveske has worked to change up bolt metallurgy to assist with this problem. My advice to bowlers interested in pushing performance of 6ARC is to buy a quality barrel and a quality bolt.

The round is very, very dirty. This usually isn't a problem but I try to throw a good amount of oil on the bolt every couple of hundred rounds to keep the gun operating smoothly and remove carbon from the bolt and upper every 500 or so. You know, basic maintenance stuff. I tend to notice issues when the gun dries out, like you will in any 556 AR. Just seems to happen a bit sooner with the arc. I am running a SilencerCo Velos LBP suppressor to get some of the carbon out during firing. I notice it is quite helpful with that and reduces recoil. I have also noticed that my velocity is less with this suppressor than “traditional” cans, probably because more gas is allowed to exit. Most of our 14.5s shoot factory 108 ELDMs around 2430fps, with the Velos I’m around 2390. I will take a slight decrease in velocity if it increases reliability. My brass is much cleaner with the LBP than with a traditional can. Makes me think it is helping keep the gun cleaner.

So what are my objectives? Pretty straight forward. Maintain or beat factory 108s in terms of speed and accuracy while keeping similar or better consistency. Once I’ve done that I want to have ammunition I can easily replicate and rely on. The main advantage to a precision gas gun is to be able to make repeatable, accurate shots with haste. Firing off multiple shots on steel before you can hear the first impact is pretty damn sick in my opinion, especially past 600yds. I wanted to see if I could do that more better with my own recipe.

Without delving into exactly what powder charge, OAL etc that one of you will copy, maybe blow yourself up and try to sue, or sell without any gain to Walter and I, here is roughly what I am doing:

-105 berger hyrbid (a gold standard)

-a stout charge weight of cfe223

-brass thats been fired a few times (i should keep track)

-cci 450s

I started working on this project in the fall using the Hornady book with several powders we had laying around, ideally finding something temp stable. Most of what I tried were too slow, under factory loading velocities. I could probably find some niche powder with good stability while maintaining high velocity but for me reloading means increasing performance and having access to components reliably at a fair price point. All that to say I compromised on temp stability to have a bunch of CFE 223. I haven't noticed much velocity change since the fall but I am also lucky to live in a relatively consistent climate. I will keep an eye on this as the summer continues to heat up.

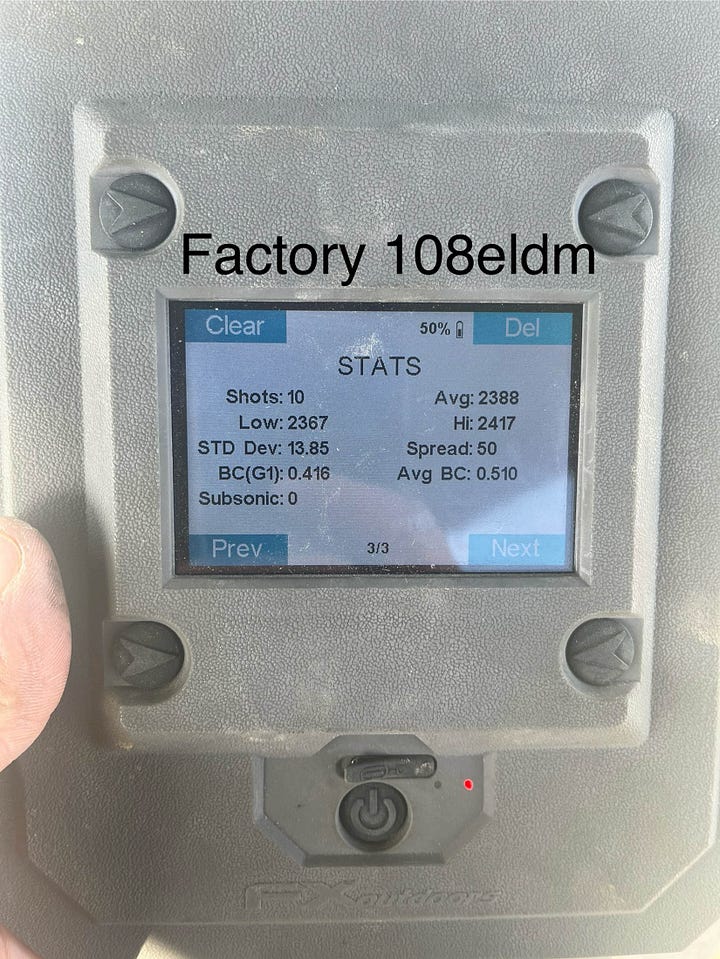

I started to jump my charge weight to increase speed. I found the spherical powders like CFE223 and LEVERevolution allow for more powder to be fit into the case. I think this is one of the challenges with 6ARC and getting superior velocities out of handloads. With a longer bullet there just isn't as much case capacity in small frame cartridges, go figure. I am at a bolt gun charge weight, so load at your own risk. I think with a quality bolt it is fine to go warmer than what is in the reloading bible for this cartridge. Seems to be the opinion of others as well. I am getting an average velocity of 2510 with the current load, which is about 120fps faster at the muzzle than 108 factory ELDM in my rifle. At 1000 yards it's about 1.5 mils less elevation hold, or about 4.5ft difference compared to factory ammo. I have verified this data in the field. My SDs are in the low teens and ES in the low 40s, roughly the same variance as the factory. Photos of two strings compared on the FX chrono. Pretty acceptable in my opinion with that much velocity increase.

I’m not interested in loading a light weight projectile in the race to gain velocity. They have their purpose but I am trying to maintain external ballistics to distance as much as possible. If I wanted to compromise Ballistic Coefficient and shoot an 80ish grain projo at 2700+ I would just shoot 556. That said I am loading the heavier end bullets and have liked the 105 Berger Hybrid. My gun shoots about 1moa regularly with fliers in both factory and handloads. With regularity I can shoot a half minute 5 round group with my handloads. I think at this point variance in accuracy has more to do with pulling a shot than it does with the rifle and ammo. Regular at or sub-minute accuracy is plenty acceptable out of a 14.5” gas gun, or most rifles in my book.

One thing I noticed when reloading fired brass is that I saw immediate accuracy increases once I started annealing my fired cases (all Hornady). My hand load groups were slightly worse than factory ammo at first which was disappointing considering how much time reloading on a single stage takes. I figured it wouldn't hurt to see what annealing would do, and saw my groups tighten up noticeably. I try to tumble my brass pretty well between loadings which isn't a big deal for me as I have over 500 pieces to work through at this point. I consistently check for split necks and other pressure signs but rarely if ever see anything not worth using. I resize, trim and measure for a mostly consistent overall case length. I have been running a cheap brass catcher just to keep better track of it and keep it less dirty in the field. Also saves getting your hands getting nasty and maybe reduces some lead exposure.

Going forward I will continue to look for signs of unstable temperatures with my current powder choice. Overall I am happy with the performance out of this 14.5. I have taken the handloads past 1000 yards with good consistency which is about all I am looking for, but I would like to stretch them further. I hear that Shellshock will be making 6ARC Nas3 casings which will be cool to push more velocity but a shame that I probably wont be able to re-use them. Feel free to DM (@demolitiondonny) me with questions related to my process. 6ARC continues to impress.

I’m assembling a 12.5 6 ARC in an armorers class in early Glocktober. I don’t have kit to reload (someday) but I have been buying up various factory loads to see what works.

As mentioned, I have 100rds. of the 108 ELDMs on order, 100 the Black 108’s, and 50 rds of 65gr VXTs.

I’ve seen HSM factory loads using the 105 Berger? Any thoughts?

The build goal is LR plinking, TX whitetail, and other mischief. Hogs, varmints… Thanks for sharing the 6 ARC info.

FWIW, I ordered a few 9mm 124gr+p Selous rounds from Discreet Ballistics. You discussed in a previous article. They should be shipping soon.

Do you crimp? I have movement with 105 hybrids using a .240 mandrel (7ish thousandths). I just picked up a .238 mandrel to try and avoid crimping.